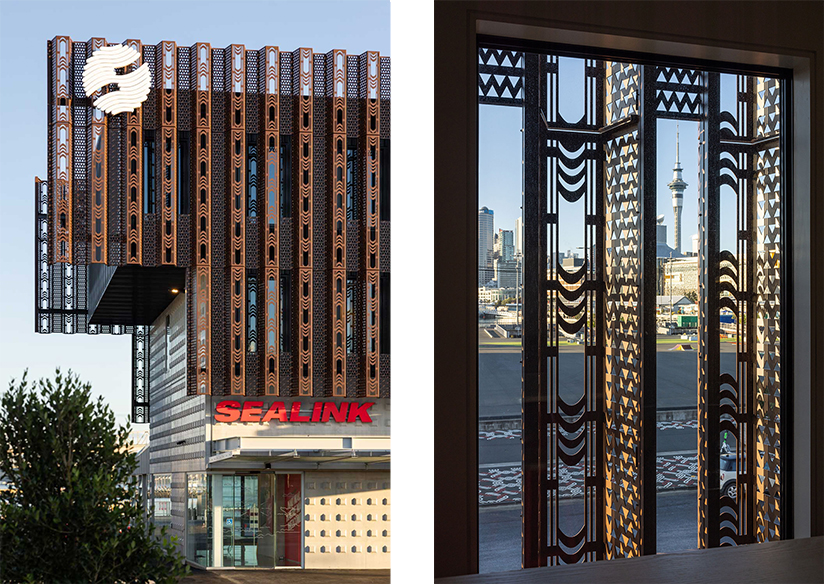

The intricate perforated facade screen designed, supplied and installed by Symonite, was fully resolved before it reached site, using factory prototyping and wind noise testing.

The award-winning Sealink Ferry Terminal on Auckland’s waterfront called for a façade that seamlessly connects the building to its marine environment – both in form and function. Designed by Architectus in collaboration with mana whenua artists, the vision was brought to life by the Symonite Design & Engineering team, who precisely modelled every aspect to meet wind and load performance requirements, all while preserving uninterrupted sightlines from within the terminal. It required engineering precision, specialist skills and expertise.

The screen system was designed from the outset with installation in mind. The hook-and-pin fixing method, combined with clear sequencing (bottom-up installation), meant the screen could be installed cleanly and consistently, avoiding on-site improvisation and leading to early completion.

The result is a 5mm marine-grade aluminium screen spanning the full face of the building, combining solid and perforated panels in a pattern by artists Maaka Potini and Ted Ngataki (Ngāti Tamaoho), inspired by Unaunahi (the scales of the fish).

A unique balance of engineering and aesthetics

‘We’ve built perforated screens before, but this was on a much larger scale and extremely intricate,’ says Symonite Senior Technical Adviser Matthew Harris. ‘It’s a true mix of art and engineering. We did extensive Strand7 analysis to ensure strength and rigidity for a highly perforated façade. Hidden details, such as cleats and angled supports, provide strength. You don’t see the fixings, but they’re critical to how the whole system performs.’

The need to ensure sightlines from the windows behind the perforated screen added complexity. ‘We couldn’t simply add horizontal stiffeners to deal with deflection, as that would have ruined the look,’ says Matthew. ‘We avoided that by carefully folding, welding and cleating the panels, and going into every nook and cranny to ensure structural integrity without compromising the design vision.’

Designing in success from the start

Careful design and planning was key. ‘We undertook local prototyping to identify any potential issues,’ says Matthew. ‘For example, we sent one prototype to Australia for wind and load testing, which identified potential wind noise through one of the verticals. We addressed this with EDPM rubber to close the gap that was causing it. We also worked closely with the structural engineers at DHC to ensure the design was practical and straightforward to build.’

Installation sequencing was also key to successful on-site installation, says Symonite Project Manager Stefan Claveria. ‘Panels were transported to site from the Symonite factory, then installed from the ground up, with the hook-and-pin system simplifying the installation process.’

‘We tried to make the installation as easy and efficient as possible. Once we had the system up and running, it worked really well. In fact, we were able to beat our targets and complete the installation ahead of time. A big part of that was working closely with the main contractor, Clearwater, on site to address any issues that came up along the way.’

An award-winning achievement

By balancing engineering with aesthetics, Symonite has built a façade that delivers on the design vision and elevates Sealink’s new ferry terminal to a unique destination for local and international travellers.

The Sealink project was the recipient of a 2025 Local Architecture Award from Te Kāhui Whaihanga NZ Institute of Architects, with the judges noting that the building ‘transcends its prosaic purpose with a folded perforated metal screen cladding that evokes the surrounding context of containers and sheet piling in a poetic way’.

The Sealink terminal is a visible, public-facing building with architectural complexity and public scrutiny, and Symonite have helped to deliver on the required design and detailing excellence. The building achieves something greater – something artful, emotional, symbolic and culturally meaningful.

‘It’s great to have that recognition,’ says Matthew Harris. ‘But more importantly, it’s been extremely well received not only by our client, but by the ferry passengers who use the building every day.’

——

PROJECT CREDITS

Service: Design, supply and installation of full-façade perforated aluminium screen

Architect: Architectus

Structural Engineer: DHC Consulting

Builder: Clearwater Construction

Photographer: Mark Scowen

Writer: Folio

Find out more

To learn more about our envelope services and solutions, get in touch with our team of experts.

Other Symonite projects