Modular off-site construction shortens construction timelines.

Symonite promotes excelling modular panelised cladding solutions that reduce the installation time on-site with several months on multi-storey residential and commercial buildings. The steel-framed frames are coming in typically sizes up to 10m long and 3.5m high.

The available solutions consist of confined, floating and overcladding systems, a wide range of cladding options, different joinery solutions with varied performance and an endless array of add-ons (louvers, juliette balconies, etc)

The scope for the use of these systems are building with minimum 4-5 storeys, rectangular shaped or with balconies, combining windows and curtain wall glazed areas and for both commercial and residential use.

Modules will be installed using specialized cranes and avoid the use of scaffolding, are excellent in confined spaces and reduce the amount of labored skill on site. The systems were tested to NZS4284 and show excelling weather, air and wind resistance, well above the required standards and complying with Passive House level of performance. Yet, the price will surprise…

For more information or request a project reference email info@symonite.co.nz or call 09 44 33 896.

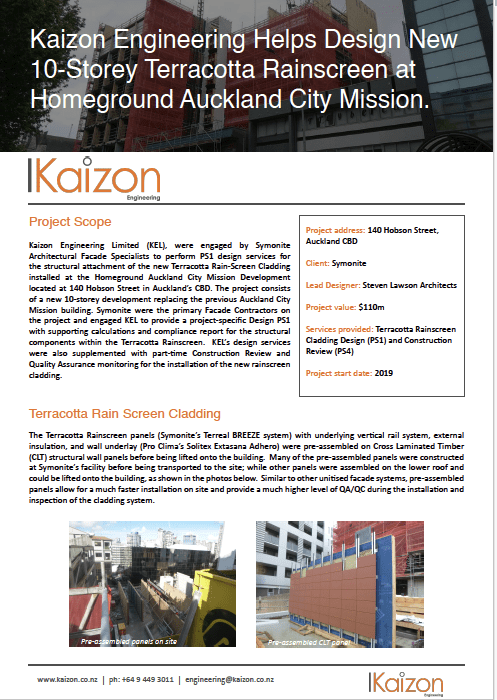

CASE STUDY : MODULAR BUILD, AUCKLAND CITY MISSION

Symonite Architectural Facade Specialists engaged Kaizon Engineering Limited (KEL) to perform PS1 design services for the structural attachment of the new Terracotta Rain-Screen Cladding installed at the Homeground Auckland City Mission Development located at 140 Hobson Street in Auckland’s CBD. The project consists of a new 10-storey development replacing the previous Auckland City Mission building.

Click the thumbnail below to read/download the Kaizon Engineering case study.